The construction industry is increasingly under pressure in terms of schedule, cost, and quality, driving strong interest in new construction solutions. One of the most prominent trends today is modular precast systems. Not only do they help shorten construction time, but they also deliver high economic efficiency and ensure project quality. So what are modular precast systems, and how are they applied in real construction projects? Let’s explore in detail with mongkimcuong.com!

Development trend of modular precast systems in Vietnam

In Vietnam, the demand for housing, resorts, industrial parks, and infrastructure is continuously rising. This creates great opportunities for the development of modular precast systems. Many companies have invested in modern manufacturing plants and applied automation technologies to improve quality and productivity.

In the future, as green building standards and energy efficiency gain more attention, modular precast systems will continue to be a promising solution, contributing to transforming traditional construction methods.

What are modular precast systems?

Modular precast systems are a construction method in which structural components or building modules are manufactured in factories according to specific dimensions and technical standards. These modules are then transported to the site and assembled into a complete building.

The process usually includes three main steps:

- Factory production: Concrete is cast in molds under strictly controlled quality conditions.

- Transportation: The modules are delivered to the construction site using specialized equipment.

- Assembly: Cranes and machinery are used to connect the modules according to design drawings.

Compared to traditional on-site construction, which requires building each component at the site, modular precast systems significantly reduce on-site workload, while minimizing the impact of weather and environmental conditions.

Why are modular precast systems increasingly adopted?

Optimizing investment and labor costs

One of the greatest advantages of modular precast systems is cost control. Thanks to mass production in factories, materials are used more efficiently, reducing waste compared to manual construction. At the same time, fewer workers are needed on-site, leading to lower labor and management costs. Moreover, minimizing unexpected expenses during construction helps investors estimate budgets more accurately from the start and avoid cost overruns.

Shortening construction time

With modular precast systems, production can take place in parallel with site preparation. Once the site is ready, modules are transported and assembled in a short time, potentially reducing construction duration by 30–50% compared to traditional methods.

This is especially important for projects that need early operation, such as housing, homestays, hotels, or temporary offices.

Ensuring quality and consistency

Components in modular precast systems are produced in factory environments with strict control over concrete mix design, strength, and dimensional accuracy. As a result, product quality is consistent, minimizing errors caused by workmanship or outdoor conditions. During assembly, joints are carefully engineered to ensure stability and safety for the entire structure.

Flexibility and scalability

Modular precast systems allow flexible designs to meet different usage needs. Investors can easily expand space by adding more modules when necessary or change functions without extensive demolition, unlike traditional construction.

Cost-to-quality efficiency when applying modular precast systems

Long-term economic efficiency

In the long run, modular precast systems offer clear economic benefits. Although initial investment costs may be comparable to or slightly higher than some lightweight solutions, their high durability, low maintenance requirements, and reduced operating and repair costs help optimize the total life-cycle cost. In addition, faster project completion enables quicker return on investment, especially for commercial projects.

Quality and durability performance

Precast concrete provides excellent load-bearing capacity, fire resistance, waterproofing, and sound insulation. When combined with proper engineering design, modular units can meet long-term usage demands and are well suited to Vietnam’s hot and humid, rainy climate. Modular buildings can achieve a lifespan comparable to traditional reinforced concrete structures.

Environmental and sustainability benefits

Factory production reduces construction waste and minimizes dust and noise at the site. Efficient material usage also helps conserve resources. These are key factors aligned with today’s green building and sustainable development trends.

Key considerations when choosing modular precast systems for your project

To maximize the effectiveness of modular precast systems, investors should consider:

- Selecting a reputable provider: with experience in design, manufacturing, and modular installation.

- Evaluating technical standards: materials, concrete strength, and connection solutions.

- Matching the intended use: residential, commercial, or industrial projects have different requirements.

- Warranty and maintenance policies: to ensure long-term stable operation.

Visiting and reviewing completed projects can also help investors gain a more objective view before making decisions.

Conclusion

It is clear that modular precast systems offer outstanding advantages in cost, schedule, quality, and sustainability. With diverse applications ranging from housing and offices to industrial and tourism projects, this is a smart choice for investors in modern construction. When properly designed and implemented, modular precast systems not only optimize project efficiency but also contribute to creating durable buildings aligned with the long-term development trends of the construction industry.

Contact ABL now via Hotline (WhatsApp): 0847912023 for detailed consultation, or refer to the precast module price list at ABL to execute your project in the fastest and most cost-effective way.

- Những mẫu nhà vườn 1 tầng đẹp mắt và dễ thi công

- Công trình nhà anh Tùng Quốc Oai hiện đại – nhà bê tông nguyên khối ABL

- Top 10 kiểu nhà vườn đẹp hiện đại hợp với mọi diện tích đất

- TOP 10+ mẫu nhà trọ module bê tông đúc sẵn tiết kiệm chi phí 2025

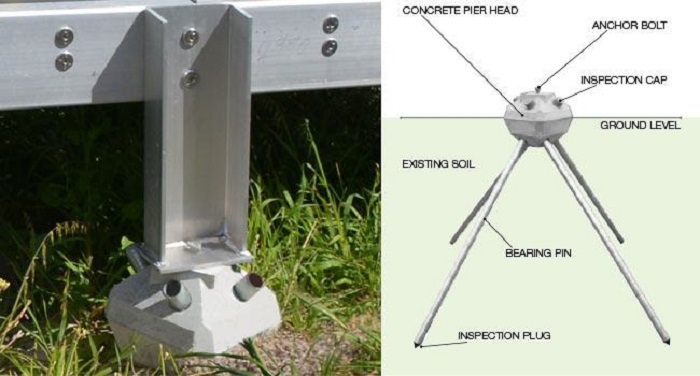

- Diamond Pier Foundation – The New-Generation Footing Solution for Modern Construction