In recent years, modular concrete construction has gradually become a new trend in the construction industry thanks to its fast construction speed, effective quality control, and cost optimization. This method is especially suitable for projects that require tight schedules, high durability, and long-term stability. Let’s explore the details together with mongkimcuong.com.

Concept of modular concrete construction

Definition of concrete modules

Concrete modules are reinforced concrete components that are precast according to standardized dimensions and designs. They can represent an entire room, a functional block, or a complete structural section of a building. These modules are manufactured synchronously in factories and then transported to construction sites for assembly into a finished structure.

In modular concrete construction, each module functions like a “large brick” within the overall system, ensuring accuracy, uniformity, and easy quality control.

Structure of a standard concrete module

A standard concrete module typically includes:

- A reinforced concrete frame serving as the main load-bearing structure

- Floors, walls, and ceilings cast monolithically or in semi-prefabricated form

- Pre-installed technical provisions for electrical, plumbing, and ventilation systems

- Connection points for linking with other modules

Depending on the intended use, a module may be partially finished or almost fully completed before being delivered to the site.

Operating principles of modular concrete buildings

Factory production

All modules in modular concrete construction are produced in controlled factory environments. This helps to:

- Control the quality of concrete, reinforcement, and casting processes

- Ensure high dimensional accuracy

- Reduce the impact of weather compared to on-site construction

Producing multiple modules simultaneously also significantly shortens the overall construction timeline.

Transportation and on-site assembly

After completion, the modules are transported to the construction site using specialized vehicles. There, technical teams assemble them according to the design drawings by:

- Positioning foundations and load-bearing structures

- Installing modules in sequence

- Connecting and finishing joints

This process is fast, involves minimal unforeseen issues, and is easy to manage in terms of progress.

Structure and materials in modular concrete construction

Precast reinforced concrete structures

Load-bearing capacity and crack resistance:

The concrete used in modular concrete construction typically has high strength and is carefully calculated to meet requirements for load-bearing capacity, crack resistance, and long-term durability. Precast structures reduce construction deviations and enhance overall stability.

High precision:

Thanks to factory production, modules achieve near-perfect accuracy, allowing for fast installation, tight joints, and minimized technical errors.

Modular connection systems

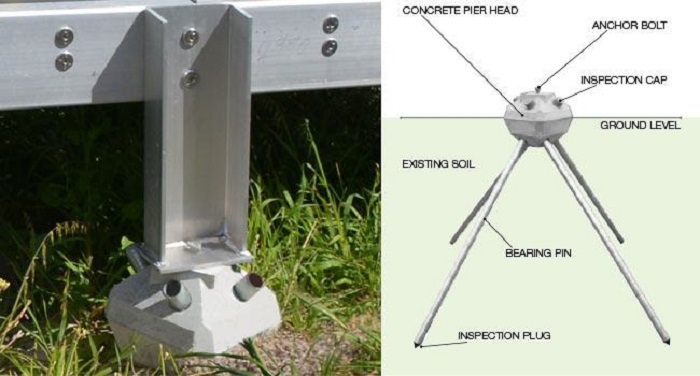

Vertical and horizontal connections:

Modules are connected using bolts, steel plates, or reinforced concrete joints. Vertical and horizontal connections ensure even load transfer and increase the stability of the entire structure.

Disassembly and expansion capability:

One advantage of modular concrete construction is the ability to disassemble or expand in the future. Additional modules can be added without significantly affecting the existing structure.

Interior and exterior finishing

Thermal and acoustic insulation solutions:

Modules can integrate insulation and soundproofing materials during the production stage, improving the quality of living and working spaces.

Design customization:

Modular concrete construction does not mean rigid design. Investors can still customize layouts, finishing materials, and architectural styles according to their needs.

Key advantages of modular concrete construction

Fast construction and reduced building time

Compared to traditional construction methods, modular concrete construction can shorten construction time by 30–50% thanks to parallel production and rapid on-site assembly. Projects such as rental housing, temporary buildings, site offices, or field hospitals are particularly well suited to this model.

Effective cost control

Because design and production are carefully planned from the beginning, modular concrete construction minimizes cost overruns during construction. Costs are clearly defined at the design stage, making it easier for investors to plan their budgets.

High durability and long service life

Concrete modules offer excellent waterproofing, high load-bearing capacity, and minimal impact from environmental conditions. Compared to many other methods, modular concrete buildings require less maintenance, helping to reduce operating costs.

Optimized use of materials

Materials are used precisely according to design specifications, reducing waste and improving overall resource efficiency.

Limitations of modular concrete construction to consider

Despite its many advantages, modular concrete construction also has certain limitations that should be carefully considered to ensure the project is planned and implemented effectively.

Requirement for precise upfront design

Since modules are prefabricated, making design changes after production is difficult. Therefore, the design phase must be carefully planned and thoroughly reviewed.

Limitations in module transportation

Transporting large modules requires suitable transportation infrastructure, especially in dense urban areas. Modules can be divided into smaller units or designed in appropriate sizes to optimize transportation and installation.

Practical applications of modular concrete construction

Modular concrete construction is widely and flexibly applied across many types of projects thanks to its fast construction speed, high durability, and ease of quality control.

Residential housing

In residential construction, modular concrete construction provides an optimal solution for projects that need quick completion while still ensuring strong structural integrity. With modular design, living spaces are logically organized to meet modern lifestyle needs.

Using concrete modules shortens construction time, reduces dependence on weather and labor, and allows homeowners to better control costs while maintaining privacy and long-term durability.

Rental housing and homestays

For rental housing or homestay models, modular concrete construction enables investors to quickly put projects into operation. The flexible modular design also makes future expansion easier as demand increases.

Commercial and service buildings

Commercial and service projects that require fast completion and a professional appearance are well suited to modular concrete construction.

Offices and showrooms

Offices and showrooms built with concrete modules can be completed in a short time, offering clean, modern spaces that are easy to reconfigure according to business needs.

Conclusion

Modular concrete construction is a modern solution that effectively meets requirements for schedule, quality, and cost in a rapidly evolving construction industry. With proper investment from the design stage and the selection of a reputable contractor, this model promises long-term and sustainable benefits for various types of projects. If you are considering using precast concrete for your home, contact ABL today for consultation and a detailed quotation. Hotline (Whatsapp): 0847912023

- Reasons why precast concrete buildings are increasingly prioritized in modern construction

- Bí quyết chọn mẫu nhà trọ đẹp hiện đại phù hợp ngân sách

- Các mẫu nhà vườn 2 tầng đơn giản, tiết kiệm chi phí cho gia chủ

- Dự án homestay Quảng Bình – nhà bê tông đúc sẵn tiện lợi, hiện đại

- Dự án nhà ở chuyên gia anh Hải Đồng Nai – thiết kế 2 tầng hiện đại, tiện nghi