Today, the construction industry is under constant pressure in terms of schedule, cost, and quality. precast modular units are emerging as a strategic solution. With fast construction speed, consistent quality control, and optimized operation, this model is increasingly becoming the preferred choice for many projects. As a pioneer in the design and construction of monolithic precast concrete modular houses and assembled concrete systems, ABL delivers a structured, practical, and highly effective approach. Join mongkimcuong.com to explore why this solution is highly valued in today’s construction market.

Definition of precast modular units

precast modular units are concrete components manufactured completely in factories according to predefined dimensions and design standards, then transported to construction sites for assembly into finished buildings. Each module may function as a structural element such as walls, floors, columns, technical cores, or even an independent functional space.

Unlike cast-in-place concrete methods, precast modular units allow most of the construction work to be completed in a controlled environment, significantly reducing on-site construction time.

Differences compared to traditional concrete construction

Traditional concrete construction relies heavily on weather conditions, labor skills, and manual on-site processes. In contrast, precast modular units are produced through an industrialized process, minimizing errors while improving accuracy and consistency in quality.

Additionally, conventional construction is typically executed in a linear sequence, whereas modular concrete systems enable parallel workflows, creating a clear advantage in project timelines.

Production and assembly principles of precast modular units

Factory precasting process

precast modular units are manufactured in factories based on detailed technical drawings. The process includes reinforcement fabrication, installation of embedded technical systems (electrical and plumbing where applicable), concrete casting, and curing under standardized conditions.

Because production takes place in a controlled environment, factors such as mix proportions, vibration intensity, and curing time are strictly managed, ensuring stable quality for each module.

Quality control in a standardized environment

One of the key advantages of precast modular units is strict quality control from the production stage. Each module is inspected for load-bearing capacity, geometric dimensions, surface flatness, and other technical requirements before leaving the factory.

This significantly reduces the risk of technical defects during installation and increases overall project reliability.

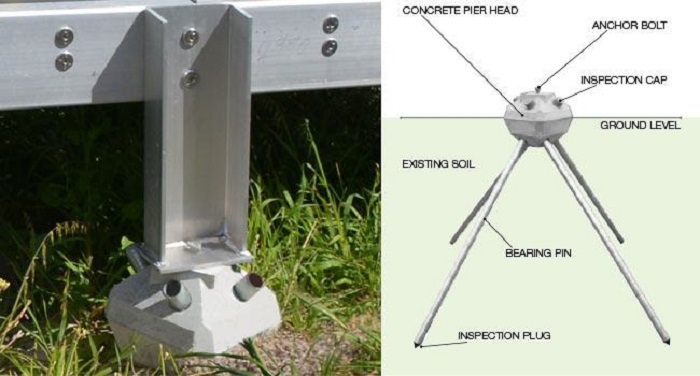

Transportation and on-site installation

After completion, modular units are transported to the site using specialized vehicles and installed by cranes. The installation process is fast and precise, following sequences calculated in advance during the design phase.

Reducing wet construction activities on-site results in cleaner job sites with less dust and noise, making this solution particularly suitable for residential areas and dense urban environments.

Why are precast modular units suitable for fast-track projects?

Shortened construction time

- Parallel production with foundation works: While foundations and infrastructure are being built on-site, precast modular units are simultaneously manufactured in factories. This approach significantly reduces waiting time between construction phases and shortens overall project schedules.

- Reduced dependency on weather: Since most work is performed indoors, module production is not affected by rain, heat, or high humidity—an important advantage in regions with unstable weather conditions.

- Fast and precise assembly: Module installation is completed quickly, often taking only days or weeks for the structural phase, compared to several months with traditional construction methods.

Reduced risk of schedule delays

- Minimized manual errors: On-site manual construction often leads to human errors. With precast modular units, standardized components greatly reduce technical mistakes.

- Fewer on-site adjustments: Thanks to integrated design and production, modular projects require fewer modifications, demolitions, or rework—common causes of construction delays.

- Easier overall schedule control: Production and installation timelines can be planned in detail, making progress easier to monitor and manage, and allowing investors greater control over project execution.

Optimized labor and indirect costs

- Reduced on-site labor requirements: Compared to traditional construction, modular concrete systems require fewer workers on-site, lowering accommodation, management, and safety costs.

- Lower extended management costs: Shorter construction duration leads to reduced project management expenses, site rental costs, financial costs, and other indirect expenditures.

- Ideal for early handover projects: For projects requiring rapid operation—such as rental housing, homestays, showrooms, or offices—early completion provides clear financial advantages.

Key advantages of precast modular units

Consistent quality and durability

Factory production ensures high precision, uniform quality, and compliance with strict technical standards. With well-controlled materials and processes, buildings using precast modular units achieve long service life and strong environmental resistance. Carefully calculated and reinforced components enhance load-bearing capacity and reduce cracking risks compared to manually cast concrete.

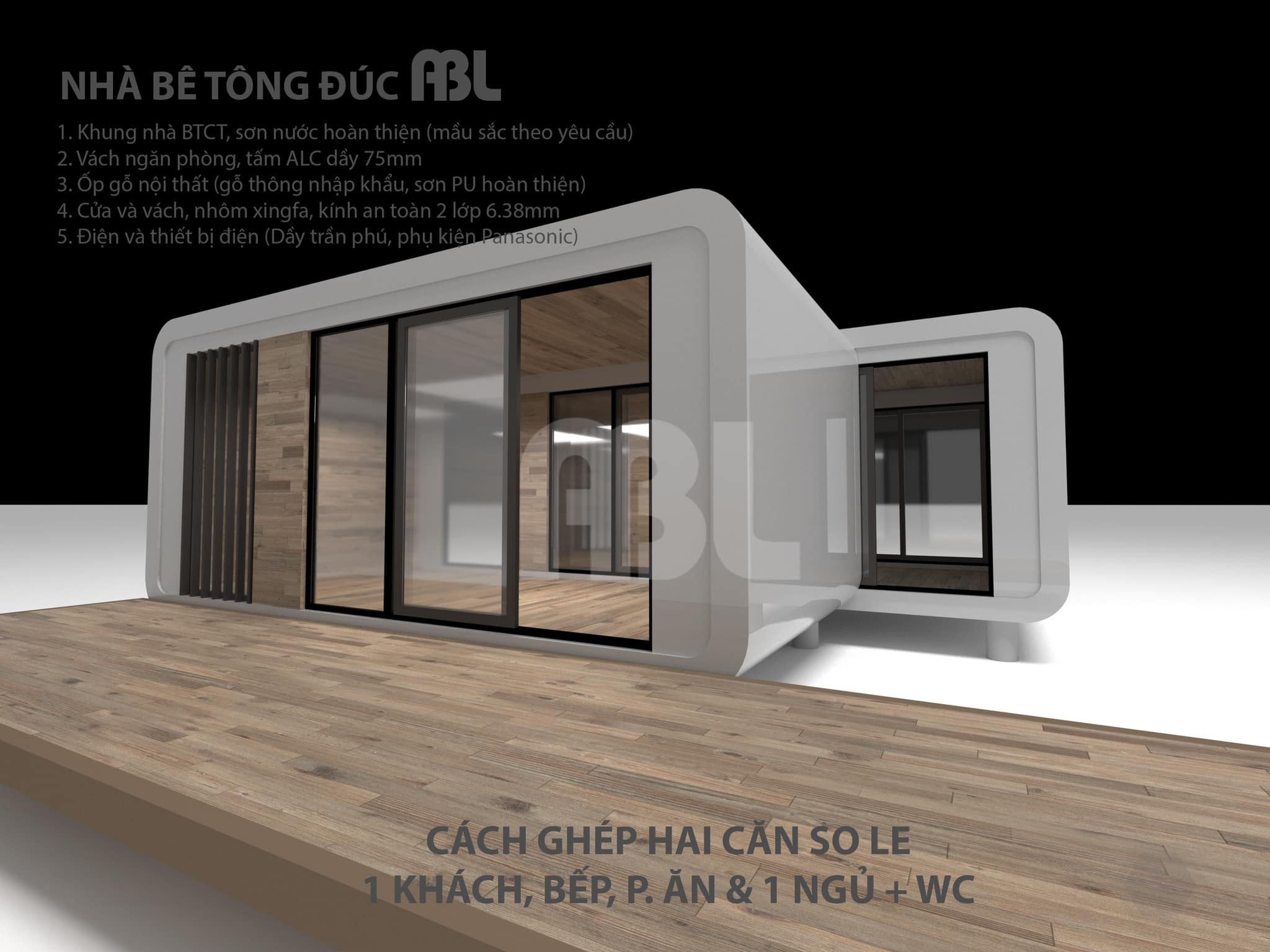

Design flexibility

Modules can be added or removed to expand scale or change functional use. From residential housing and commercial buildings to industrial facilities, precast modular units adapt flexibly. They also integrate well with various architectural styles, from minimalist and modern to industrial designs.

Practical applications of precast modular units

Residential buildings requiring fast completion

precast modular units are ideal for single-family houses, rental homes, and homestays, helping shorten construction time, enable early operation, and optimize cash flow—especially effective in remote areas or locations with limited labor availability.

Commercial and service buildings

This solution is widely applied in offices, showrooms, retail stores, and homestays, meeting demands for fast construction, flexible expansion, timely completion for opening, and easy replication of business models.

Key considerations when selecting precast modular units for a project

Initial design stage

Modules must be calculated from the beginning to ensure designs align with modular dimensions and characteristics. Strict adherence to module sizes optimizes construction efficiency and minimizes additional cutting or adjustments. Design coordination between architecture, structure, and technical systems is essential to reduce changes during production and installation.

Selecting production and construction partners

Priority should be given to contractors with proven experience in modular construction and a strong portfolio of similar projects. Modern factory capacity is crucial for ensuring production quality and schedule adherence. Clear quality control processes further reduce technical risks.

Transportation and installation conditions

Construction sites must provide sufficient space for vehicles and cranes, suitable transportation infrastructure for large components, and adequate lifting equipment to ensure safe and precise installation.

Conclusion

precast modular units clearly demonstrate their role as an effective construction solution for projects requiring fast schedules, stable quality, and cost control. With advantages such as parallel construction, reduced weather dependency, consistent quality, and flexible design, this model is especially suitable for modern residential, commercial, and service projects.

As a specialist in designing and constructing monolithic precast concrete modular houses and assembled concrete systems, ABL delivers comprehensive solutions from design and production to installation, helping investors shorten timelines while maintaining durability and aesthetics. To better plan your investment, you can refer to ABL modular house pricing or contact Hotline (WhatsApp): 0847912023 for detailed consultation.