Precast concrete buildings are increasingly becoming the preferred choice for many investors, construction companies, and project developers. Beyond shortening construction timelines, this model offers greater control over quality, budget, and long-term sustainability. So what makes precast concrete buildings more widely adopted in modern construction? Let’s explore the core reasons together with mongkimcuong.com.

What are precast concrete buildings?

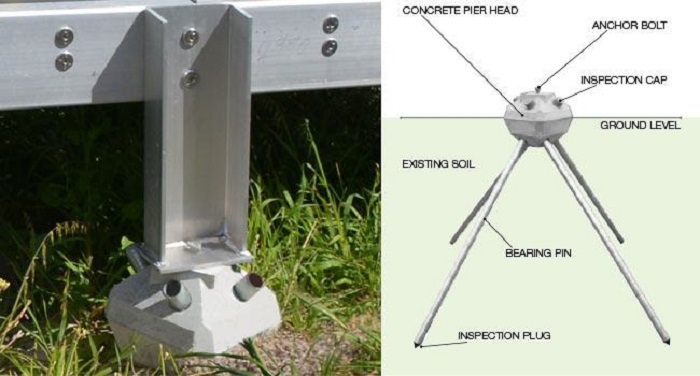

Precast concrete buildings are a construction method that uses concrete components manufactured in factories according to technical drawings, then transported to the site for full assembly. These components may include columns, beams, slabs, walls, staircases, wall panels, and precast foundations.

Unlike cast-in-place concrete, the entire process of forming, curing, and quality control for precast concrete takes place in a factory environment. This ensures higher accuracy and better consistency across all components.

Shortened construction time – a major advantage of precast concrete buildings

One of the most important reasons precast concrete buildings are prioritized is their ability to significantly reduce construction time.

Traditional construction requires sequential steps such as formwork installation, rebar fixing, concrete pouring, curing, and dismantling. With precast concrete, structural components are completed in advance before being delivered to the site. On-site work mainly involves assembly, connections, and finishing.

In addition, component production can proceed in parallel with site preparation, foundation, and infrastructure works. This can reduce total construction time by 20–50% depending on project scale, making it especially effective for fast-track projects such as factories, warehouses, modular housing developments, or industrial facilities.

Consistent and stable quality control

Construction quality is critical to every project. For precast concrete buildings, factory-based production provides a significant advantage in quality control.

Components are cast in a controlled environment with standardized machinery, molds, and strict inspection procedures. Concrete mix ratios, load-bearing capacity, surface flatness, and geometric dimensions are carefully checked before delivery.

As a result, common issues found in traditional construction—such as surface voids, dimensional inaccuracies, insufficient concrete strength, or inconsistent quality between structural elements—are minimized.

Optimized overall costs for investors

Many people assume that precast concrete is more expensive. However, when considering the total life-cycle cost of a building, it often proves to be a more economical solution.

First, shorter construction time reduces labor costs, site management expenses, and delays-related overruns.

Second, mass production in factories optimizes material usage and reduces waste compared to on-site concrete casting.

Third, consistent quality lowers maintenance and repair costs during operation.

Thanks to accurate cost estimation from the outset, precast concrete buildings allow investors to better control budgets and reduce the risk of cost overruns—an issue common in traditional construction projects.

Reduced dependence on weather and labor

Cast-in-place concrete construction is highly affected by weather conditions such as rain, extreme heat, or high humidity. These factors not only delay progress but also directly impact concrete quality.

In contrast, precast concrete components are produced indoors and are largely unaffected by weather. On-site work focuses on installation, allowing construction to proceed more steadily and continuously.

This approach also reduces reliance on highly skilled on-site labor, which is becoming increasingly scarce and costly in today’s construction industry.

Suitable for a wide range of building types

Another notable advantage of precast concrete buildings is their flexible application across various construction types:

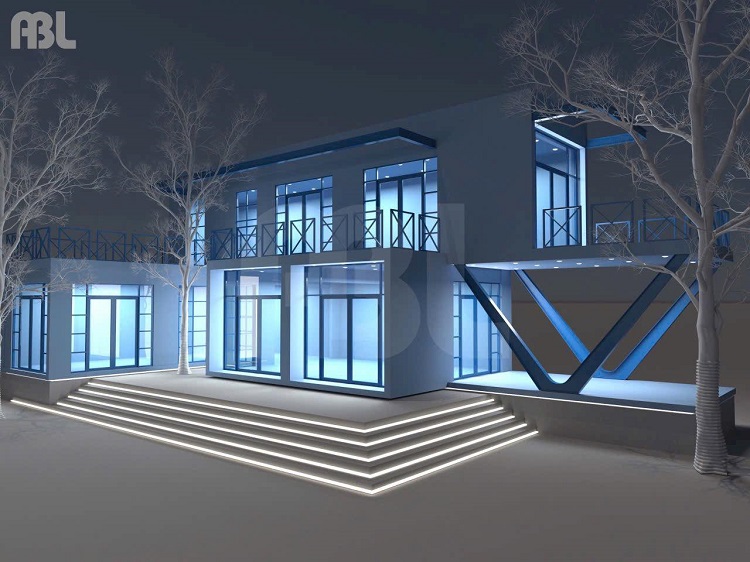

- Residential buildings: modular houses, townhouses, social housing

- Office buildings: flexible layouts, easy future expansion

- Homestays and resorts: fast construction, uniform quality, reliable control

Thanks to modular design capabilities, precast concrete solutions perform well for both small-scale projects and large, complex developments.

Flexibility in design and future expansion

Some concerns exist that precast concrete buildings may limit architectural creativity. In reality, advances in manufacturing technology and design software have made modern precast components highly adaptable.

Investors can easily modify layouts, expand spaces, or add floors in the future through modular structural systems. This is particularly suitable for businesses that expect to scale operations or change building functions over time.

Meeting sustainable construction trends

Sustainable construction is becoming a global priority. Precast concrete buildings are highly regarded for their ability to reduce environmental impact.

Centralized production allows better control of material consumption, minimizes construction waste, and reduces dust and noise at job sites. Moreover, optimized designs and the long lifespan of precast components reduce the need for frequent repairs or replacements.

These advantages make precast concrete an attractive option for projects aiming to meet green building standards, improve energy efficiency, and support sustainable development.

Key considerations when choosing precast concrete buildings

To maximize the benefits of this construction model, investors should pay attention to several important factors:

- Select component manufacturers with certified factories, production lines, and clear technical standards

- Ensure integrated design from the beginning to achieve precise assembly

- Evaluate the contractor’s construction capacity and practical experience

Close coordination between design, manufacturing, and installation is the key factor determining the overall quality of a precast concrete building.

Conclusion

With outstanding advantages in construction speed, quality, cost efficiency, and sustainability, precast concrete buildings are steadily becoming a preferred solution in modern construction. Beyond large-scale projects, this model also opens new opportunities for residential and commercial developments in the future. For detailed cost information, you can refer to the pricing table to better estimate your investment budget.

For consultation, please contact Hotline (WhatsApp): 0847912023.

- Kinh nghiệm thiết kế nhà đúc bê tông thành căn hộ nhiều phòng đầy đủ tiện nghi

- Thiết kế sân vườn đẹp đơn giản ở nông thôn với chi phí thấp

- Lưu ý thi công nhà bê tông đúc: Đừng để chủ quan hôm nay thành gánh nặng ngày mai

- Đặc điểm module V05A tại ABL và ứng dụng chi tiết

- Bí kíp thi công nhà vườn nhỏ – top 4 mẫu nhà vườn nhỏ đẹp nhất