As the construction industry faces increasing pressure to innovate in terms of technology, project timelines, and sustainability, new building methods are gaining attention worldwide. Among them, the precast modular building systems is widely recognized as a breakthrough solution that addresses many of the limitations of traditional construction. In Vietnam, forward-thinking companies such as ABL, a specialist in monolithic precast and modular concrete construction, have successfully applied this system to real-world projects. Together with mongkimcuong.com, let’s explore what a precast modular building systems is and why it is considered a future-oriented, sustainable solution for the construction industry.

What is a precast modular building systems?

A precast modular building systems is a building method in which structural components made of reinforced concrete are manufactured off-site in a factory, then transported to the construction site for assembly. These prefabricated modules may include walls, floors, columns, beams, or even fully finished functional spaces such as residential rooms or bathrooms.

Unlike conventional construction, where most activities take place on-site, modular concrete construction shifts a large portion of the work into a controlled factory environment. This approach allows for higher precision, consistent quality, and reduced exposure to weather-related disruptions. Compared to lightweight modular solutions made of steel frames or shipping containers, building systems offer superior durability, sound insulation, thermal performance, and overall service life.

Structure and working principles of precast modular building systems

Key components of the system

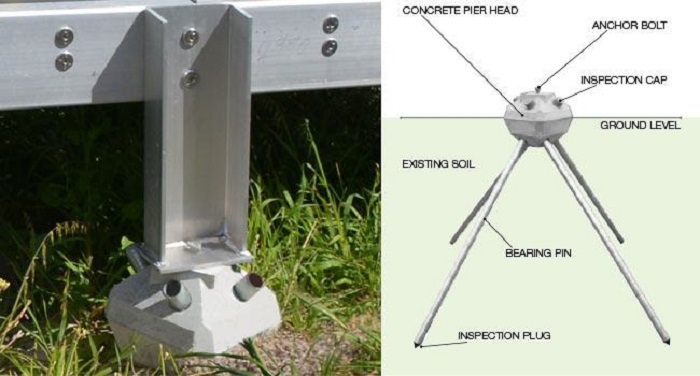

A typical precast modular building systems consists of precast concrete elements such as floor slabs, load-bearing wall panels, columns, and beams. These components are designed according to standardized specifications, ensuring accurate alignment and seamless assembly on-site.

Equally important is the connection system. Depending on design requirements, modules can be joined using high-strength bolts, dry connections, or wet joints with cast-in-place concrete. Many advanced systems integrate electrical conduits, plumbing lines, and basic finishes directly into the modules during factory production, further reducing on-site work.

Assembly and construction process

The process usually begins with detailed design and engineering, followed by the fabrication of concrete modules in a precast factory. While foundation work is carried out on-site, modules are produced simultaneously, allowing parallel workflows. Once completed, the modules are transported using specialized vehicles and installed with cranes. The precise, planned assembly process enables much faster project completion compared to traditional construction methods.

Key advantages of precast modular building systems

Significantly shorter construction time

One of the most notable benefits of precast modular building systems is its ability to shorten project schedules. Because module fabrication and site preparation occur concurrently, overall construction time can be reduced by 30% to 50%. This advantage is especially valuable for projects with strict deadlines or urgent occupancy requirements.

Superior quality and durability

Factory-controlled production ensures consistent quality and compliance with technical standards. Modular concrete buildings exhibit excellent structural performance, high load-bearing capacity, and long service life. These characteristics make them suitable for projects with stringent safety and durability requirements.

Cost optimization and reduced labor dependency

Although initial investment costs may be higher, modular concrete construction often results in lower total lifecycle costs. Savings come from reduced material waste, minimized delays, fewer on-site errors, and lower dependence on skilled labor. This is particularly relevant in markets facing labor shortages or rising labor costs.

Limitations and challenges of precast modular building systems

Despite its advantages, precast modular building systems also presents certain challenges. The upfront investment required for precast factories, molds, and standardized design systems can be substantial. Additionally, the high level of design standardization limits last-minute architectural changes. Transportation of large modules can also be challenging, particularly in dense urban areas with restricted access.

Is precast modular building systems a smart investment?

In Vietnam and many other developing markets, urban growth and housing demand are driving interest in industrialized construction methods. Government policies promoting green building, energy efficiency, and construction industrialization are expected to further support the adoption of modular concrete systems over the next 5 to 10 years.

Experts agree that precast modular building systems is especially suitable for large-scale projects with repetitive designs and tight schedules. Investors should carefully evaluate initial costs against long-term benefits. From a strategic perspective, this method represents a sustainable and future-proof investment.

Frequently asked questions about precast modular building systems

Is a modular concrete building durable?

Yes. Thanks to reinforced concrete structures and strict factory quality control, modular concrete buildings often match or exceed the durability of traditional buildings.

Is precast modular building systems more expensive?

Initial costs may be higher, but total lifecycle costs are usually lower due to time savings, reduced waste, and lower maintenance expenses.

How long does precast modular building systems take?

Depending on project scale, building systems time can be reduced by 30% to 50% compared to conventional methods.

Can designs be customized?

Design flexibility is possible within standardized modules, although building systems is more limited than in traditional construction.

Conclusion

In summary, the precast modular building systems is more than just an alternative building method, it is a comprehensive solution to the challenges of speed, quality, and sustainability in modern construction. As a pioneer in monolithic precast and modular concrete construction, ABL provides end-to-end design and construction solutions tailored to real project needs. For a detailed and transparent view of the costs, you can refer to the ABL concrete modular house price list.

Contact us now via Hotline (Whatsapp): 0847912023 for advice.

- Update on 5 Prefabricated Concrete Modules from ABL – Detailed Pricing and Complete Project Solutions

- Công trình nhà anh Tùng Quốc Oai hiện đại – nhà bê tông nguyên khối ABL

- Nhà anh Phong Quảng Trị ấn tượng ngay từ cái nhìn đầu tiên với module V05B

- Nhà anh Huy Buôn Ma Thuột – Module V05-A sang trọng, thi công nhanh

- Dự án nhà module bê tông đúc làng sinh thái Quảng Nam – ABL