The rapid development of the modern construction industry is driving the increased adoption of precast concrete components across a wide range of projects, from residential buildings to large-scale infrastructure. With the ability to shorten construction time, improve quality control, and optimize costs, this solution is emerging as a strategic choice for many investors. ABL, a company specializing in the design and construction of monolithic precast concrete modules and assembled concrete structures, is actively shaping this trend. Together with mongkimcuong.com, let’s explore the real-world value of precast components in today’s construction sector.

What Are Precast Concrete Components?

Definition

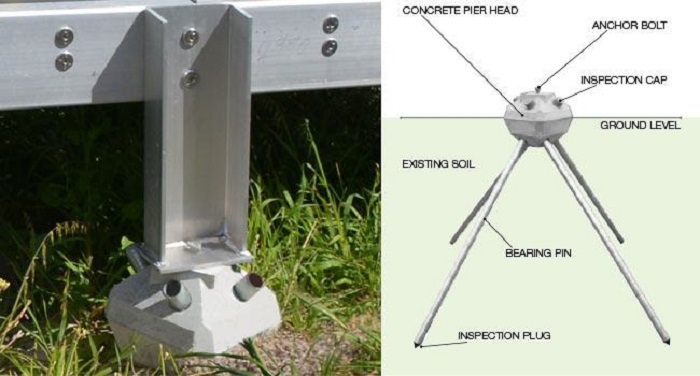

Precast concrete components are structural elements manufactured, molded, and fully cured at a factory before being transported to the construction site for installation. These components may include columns, beams, floor slabs, wall panels, foundations, staircases, box culverts, drainage channels, and more—depending on project requirements.

What makes precast components stand out is the strictly controlled production environment, ensuring far greater accuracy and consistency compared to traditional cast-in-place concrete.

Standard Manufacturing Process of Precast Concrete Components

The creation of a precast concrete component typically involves the following steps:

- Detailed design and load-bearing calculations

- Preparing steel molds according to exact dimensions and shapes

- Pouring concrete using precisely measured mix ratios, often with high-strength grades

- Compacting the concrete to eliminate voids and increase density

- Curing in a controlled environment to accelerate strength development

- Quality inspection and approval before leaving the factory

Standardizing these steps ensures each component achieves high durability, stability, and uniform quality.

Why Precast Concrete Components Are Becoming a New Trend

1. Significantly Faster Construction Speed

A primary reason many investors choose precast concrete is that construction can proceed 3–5 times faster than traditional methods. Cast-in-place concrete requires formwork installation, drying, and curing time, while precast components only need to be transported and assembled.

This dramatically shortens project timelines—particularly valuable in factories, warehouses, industrial parks, or infrastructure developments with urgent schedules.

2. Consistent, Factory-Standard Quality

Factory production of precast concrete allows precise control over:

- Concrete mix ratios

- Compressive strength

- Curing conditions

- Dimensional tolerances

Such consistent quality is difficult to achieve on-site due to weather conditions, varying worker skill levels, and unpredictable environments. As a result, precast concrete delivers superior long-term durability and minimizes cracking or settlement issues.

3. Reduced Labor and Lower Unplanned Costs

Precast construction reduces on-site labor requirements by more than 60%. There is no need for formwork, curing time, or additional maintenance during concrete hardening.

Additionally, faster progress means lower costs for project management, machinery, supervision, and other indirect expenses.

4. Less Noise, Less Dust, and Greater Safety

Traditional concrete pouring introduces risks such as:

- Formwork collapse

- Uneven concrete placement

- Cracking due to poor curing

Meanwhile, precast components rely mainly on assembly, making them suitable for urban areas, residential zones, and commercial centers where noise and dust must be minimized. They also significantly improve on-site safety.

5. Alignment With Sustainable, Eco-Friendly Construction

Centralized production reduces material waste, limits construction debris, and promotes efficient reuse. This aligns with global trends toward green building and sustainable development.

Advantages and Disadvantages of Precast Concrete Components

Key Advantages

Precast concrete components offer a wide range of benefits that make them increasingly popular in modern construction. Their high durability and long lifespan result from factory-controlled curing conditions, ensuring each component achieves optimal strength and resistance to environmental impacts. They also provide excellent load-bearing performance, making them ideal for large-scale structures such as bridges, industrial buildings, and multi-story projects.

Another standout advantage is rapid installation, which allows contractors to maintain reliable project schedules, reduce labor requirements, and minimize disruptions at the construction site. Precast components also deliver remarkable flexibility, enabling easy expansion, modular construction, and adjustments in architectural design. In addition, they ensure consistent aesthetics and precise dimensions, contributing to smoother assembly and visually uniform structures.

Notable Limitations

However, precast concrete is not without limitations. Transportation costs can be significant when projects are located far from production facilities, especially for oversized components. The installation process also requires specialized lifting machinery, which may be difficult to operate in confined or dense urban environments. Furthermore, designers must carefully consider transportation constraints, ensuring that each component’s size and weight align with local road regulations and logistical capabilities.

Despite these challenges, with well-planned logistics, thoughtful design, and experienced contractors, precast concrete consistently offers greater overall efficiency and quality compared to traditional cast-in-place methods.

Standards for Precast Concrete Components

To ensure high construction quality, precast concrete components must comply with prescribed standards, including:

Material Requirements

- Concrete must reach design strength to ensure durability, stability, and long-term structural performance.

- Steel reinforcement must meet all mechanical, tensile, and quality standards to guarantee safety, proper load transfer, and reliability for precast components.

Design & Production Requirements

- Ensure resistance to bending, shear, and torsional forces, allowing each precast component to perform reliably under varying load conditions.

- Dimensional tolerances must fall within allowable limits to maintain accurate assembly, proper alignment, and consistent structural integrity throughout the project.

Quality Inspection Requirements

- Testing concrete compressive strength to confirm durability and meet design specifications.

- Checking surface quality, density, and voids to prevent defects affecting longevity.

- Inspecting steel reinforcement placement and volume to ensure proper load transfer.

Strict compliance ensures long-term stability, safety, and optimal performance.

Reputable Precast Concrete Contractor

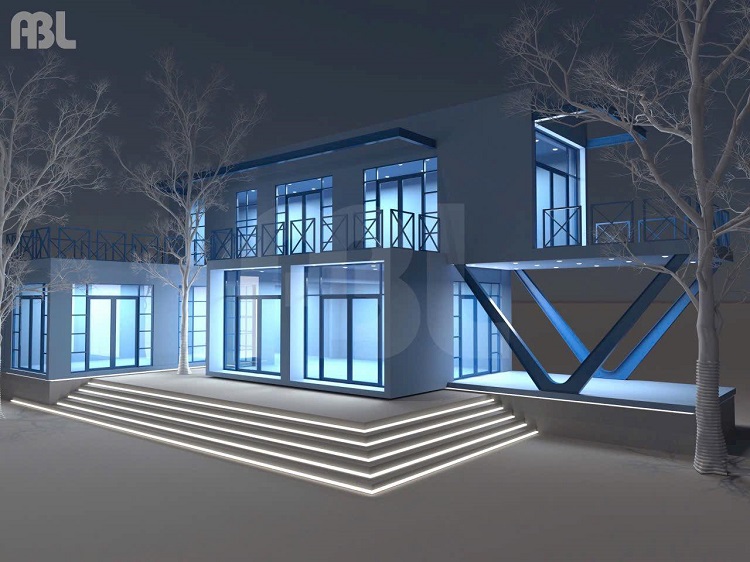

ABL – Van Phuc Co., Ltd. is a leading provider of precast concrete manufacturing and installation services. With experienced engineers, large-scale factories, and advanced machinery, ABL offers:

- Customized component design for each project

- Manufacturing compliant with all required standards

- Accurate and safe installation

- Fast construction schedule and competitive pricing

The company has successfully delivered numerous residential and infrastructure projects, earning strong recognition for quality and durability.

Conclusion

Precast concrete components not only accelerate construction, ensure consistent quality, and reduce overall costs, but also align with the rising demand for sustainable building solutions. This is why precast technology has become one of the most influential trends in modern construction.

If you are planning a project that demands speed, durability, and high safety, precast concrete components are a choice worth serious consideration. Contact ABL today for professional consulting and detailed quotations. Hotline (Whatsapp): 0847912023

- 10 lợi ích vượt trội khi chọn xây nhà bê tông đúc nguyên khối

- Precast modular units – A Smart Choice for Projects with Tight Schedules

- Gạo House – Buôn Ma Thuột – thiết kế không gian nội thất hiện đại linh hoạt không thể rời mắt

- Các mẫu thiết kế nhà vườn đẹp tạo nên không gian sống đẳng cấp

- Nhà vườn chữ L có gì đặc biệt? Top 3 thiết kế đặc sắc hiện nay